A BRIEF DISCUSSION ON THE PACKAGING TECHNOLOGY BEHIND THE NEW UVC LED INDUSTRY STANDARD

Jul 21, 2020

As the global fight against COVID-19 enters the white-hot stage, public safety and health's need for virus management and control changes from passive protection to active elimination. The state has published a new edition of GB28235-2020 "Hygienic Requirements for ULTRAVIOLET Disinfectors", which makes more standard, more scientific and more suitable for the market in the ultraviolet disinfection norms. The new industry guidelines will be implemented from November 2020 to regulate the market and guide the good development of the industry.

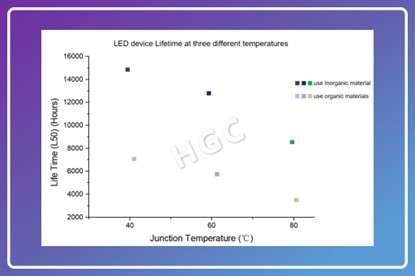

As well known in the industry, LED packaging is the core link to ensure high performance products. Currently, UVC - LED the market a large number of organic materials packaging, such as organic material such as silica gel, resin, UVC under short-wave ultraviolet radiation ability is extremely strong, with environmental temperature and humidity changes, the ultraviolet resistance fell sharply, this kind of organic material products in work after period of time, there will be changes in appearance and performance, such as filling agent cracking or binder lens loss, influence UVC - LED performance and reliability for a long time. Due to the packaging characteristics of organic materials, such as air permeability and moisture permeability, water vapor in long-term high-humidity environment can easily enter the surface and interior of the chip, seriously affecting the service life of the product.

Advantages of heat dissipation and service life of all inorganic products

As the world's top high-end LED chip and light source supplier, deep research and development of UVC-LED technology for many years, in order to improve the light output efficiency and reliability of devices, unremitting efforts to technological innovation. At present, Huaxin has received hundreds of thousands of DUVLED extinction light source products from Europe and Southeast Asia. To meet the high reliability consumption demand, Huaxin has launched advanced all-inorganic packaging technology to meet the application market demand:

Total inorganic packaging technology

Uvc-led adopts aluminum nitride (AlN) ceramic support with good thermal conductivity and inorganic packaging with pure quartz glass lens; The chip was welded by hot pressing eutectic under the environment of inert gas and reducing gas mixed protection, which further increased the electrical connection efficiency, reduced the cavity rate at the same time, stabilized the LED junction temperature, and adopted the AR anti-permeability technology, so that the pure quartz lens with full inorganic packaging has a higher light output efficiency (>95%). The whole manufacturing process achieves the "zero" use of organic materials. Through vibration, drop and other related tests, this series of devices reaches THE level of IP68. Related manufacturing technology has applied for national invention patent, and the products have passed the European Union certification, and can be sold in the European Union and other overseas markets.

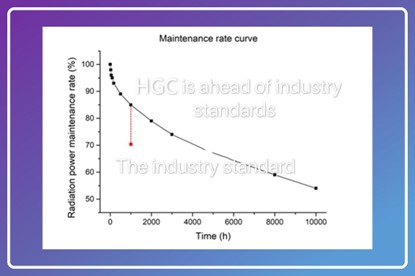

Life test is also one of the key requirements of the new NATIONAL standard of 2020. After the uv lamp is turned on steadily for 5 minutes, the attenuation change of optical output will be measured. When the optical output efficiency is lower than 70%, continuous working time must ≧1000hr before being deemed qualified. The new national standards have many mandatory requirements, including product quality, packaging materials and cooling technology. Huabing core is completely inorganic package, not susceptible to external environment, with efficient electrical interconnection and reliable packaging strength, it is in the leading level of the industry.

Performance maintenance curve of HGC all inorganic products

The pursuit of higher luminous efficiency

LED works normally under power drive, which is a process of converting electric energy into light energy. Traditional UVC LED(265-280nm) has a lower external quantum efficiency (EQE) than UVA LED(365-405nm). 95% of the electric energy will be converted into a certain amount of heat energy, and only 5% of the electric energy will be released in the form of photoelectrons. Through the optimization of chip side emitting light and the coating technology of high anti-DUV band, hua core can increase the luminous extraction rate. Its packaging product UV35E under 2 w electrical break through ascension, the output ultraviolet (uv) radiation flux Φ > 40 mw. UV68E under 8 w electrical output Φ ultraviolet (uv) radiation flux of 180 mw, meet 60 °, 120 ° angles of light, which can realize batch supply ship. At present this high power UV lamp bead technology has done the related patent review, for the specific customer priority supply.

At present, the world is in an active epidemic prevention period, and the supply and demand of the whole UVC upstream and downstream industrial chain are urgent. It is believed that with the penetration and implementation of the new NATIONAL standard, the competitive market will return to rational demand, and manufacturers with leading technologies and products in line with the national standard will inevitably become the industry's first choice. In the future, Huashin technology will continue to focus on technology development, make full use of the team's technical advantages, transform its own scientific research results and launch UVC devices and solutions with higher cost performance, higher light efficiency and more reliability, which can be widely used in indoor air disinfection in public Spaces, such as classrooms, hospitals and shopping malls; Flow water elimination and industrial water treatment, etc.