HGC Releases New ADB Matrix Light Source Module, Leading the Intelligent Headlight Localization Trac

Mar 02, 2023

Driven by the global wave of automotive intelligence, automotive lighting is moving from a single lighting to a multifaceted development of intelligent lighting, digital projection, and interactive entertainment, and the ADB intelligent matrix headlamps have emerged as a result. At the same time, the strong rise of China's new energy vehicles more domestic light source enterprises to bring huge market opportunities, how to break through the high pixel refinement of lighting and intelligent lighting expression has also become a new breakthrough direction of domestic automotive light source.

Recently, HGC debuted the new 102 Pixcell ADB matrix light source module with finer zoning, denser pixels, and more cost-effective features, to provide one-stop, integrated ADB headlight solutions with industry-leading light source chip, optical device testing strength and forward-thinking to help speed up the process of localization of intelligent vehicle lights.

Exclusive technical solution with high performance and high reliability

Intelligent ADB headlight consists of matrix light source module, sensing system and control system, and utilizes independently adjustable zoned lighting to realize the adaptive transformation of high beam light pattern to ensure glare-free and safe driving. The number of matrix light source pixels and its resolution have a decisive impact on the performance of ADB headlamps.

Led by HGC's "C²O-X" cutting-edge technology core, the ADB matrix light source module released this time adopts the "CSP on TIM" technology route, using self-developed automotive-grade high-efficiency flip-chip, combined with advanced CSP sealing and testing technology. Through the ceramic-based hot-pressing eutectic process, 102 CSP lamp beads are highly integrated, and each pixel is individually controlled by the driver, giving the ADB light source module the ability of fine zoned lighting.

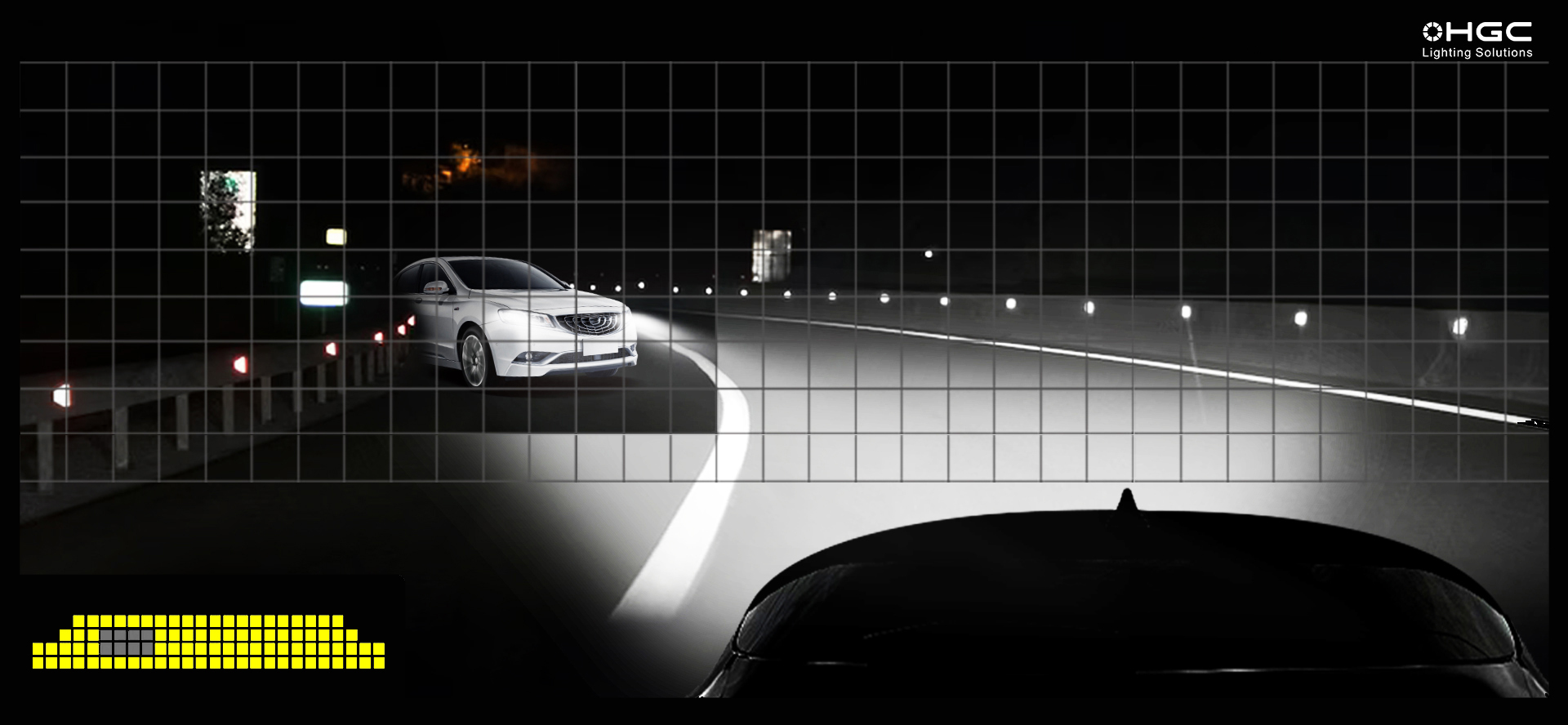

HGC ADB matrix light source module image effect display

Fine Zoned Illumination, Pixel Pitch Reduced to Micron Levels

The current intelligent ADB headlight source technology is mostly a conventional discrete array patch solution, with a small number of pixels, large size and decentralized layout (pixel pitch of 1~2mm), resulting in low brightness, low resolution and large module size of the ADB headlight, and a large pixel pitch that requires the addition of a complex silicone resin to prevent crosstalk between the light sources.

Based on the core technology advantage of self-developed chip and CSP sealing and testing, HGC uses DOB (Driver on Board) program to assemble the light source board and driver board in a face array with Underfill bottom filling process, which can achieve the pixel pitch <100μm, much smaller than the conventional discrete array patch program, which not only realizes more pixels in a compact arrangement, but also completely blocks the side of the light to solve the problem of light crosstalk, which is conducive to the ADB headlamp. This not only achieves more pixels in a compact arrangement, but also completely blocks the side light out to solve the light crosstalk problem, which is conducive to the streamlining of the internal structure of the ADB module and the optimization of the secondary optical design, and at the same time reduces the cost of the whole lamp.

HGC ADB matrix light source module zoned lighting effect display

Vertical Integration of Technology to Accelerate Domestic Substitution

The high technical threshold of automotive-grade products and the difficulty of certification largely restrict domestic light source enterprises from entering the automotive supply chain, while the high cost caused by monopoly will result in the new generation of intelligent automotive lamps not penetrating the market as fast as expected.

HGC adopts vertically integrated (IDM) mode of operation, and is one of the few high-end semiconductor light source enterprises in China that have mastered the core technology of the whole industry chain, such as light source chip design, manufacturing, packaging and testing, and have the ability to integrate the design of optics, structure, electronics and so on. In response to the technology, production, application pain points and demand, HGC uses self-developed chip and advanced packaging and testing technology to independently develop highly reliable and cost-effective automotive light source, which is now widely used in front and rear-mounted markets including ADB headlamps, and extends to the field of in-vehicle MiniLED backlighting display and in-vehicle LIDAR to provide one-stop automotive light source solutions from chip, packaging and testing, module to end-use applications.

At present, the company has obtained IATF16949 automotive quality management system certification, self-developed automotive light source has passed CE, RoHS, LM-80 and other standards, and successfully applied to domestic well-known car companies, stable delivery for more than a year, highlighting their own product power at the same time, but also for the localization of automotive light source to speed up the help.

Since its establishment, HGC has always insisted on technological innovation as the core driving force, invested heavily in R&D and accumulation with forward-looking strategic vision, and strived to promote the localization of high-end light source by adhering to its original intention. For ADB headlight application, HGC will follow the company's Mini/Micro LED R&D route, integrate the technology advantages of the whole chain of high-end light sources, and advance to create a smaller light source and higher pixel integration matrix light source program, so as to provide high-quality domestic automotive light source for the majority of automobile enterprises.