Packaging technology upgraded again, HGC mass production UVC-LED WPE breaks through 6%!

Aug 24, 2022

UVC-LED market development potential is huge, and the trend that it will eventually replace the traditional ultraviolet mercury lamp is also the industry consensus. However, constrained by the photoelectric conversion rate, performance, price, etc., the large-scale commercialization of UVC-LED has not yet broken out. Recently, HGC's new inorganic UVC-LED high luminous efficacy products have made another breakthrough, with WPE increased to 6% and effective life time of L70>30,000h, and have been realized in mass production and can be supplied quickly, which will add bricks and mortar to promote large-scale commercialization of UVC-LED industry.

Currently, UVC-LED packaging technology is still developing in the direction of low thermal resistance, high reliability, high luminous efficacy and long life. The new 3535 high luminous efficacy UVC-LED series adopts the new self-developed packaging technology and light extraction technology, and has made significant breakthroughs in WPE, airtightness and heat dissipation management.

WPE Increased to 6% 丨Technology Breakthrough Again

The light output efficiency of UVC is greatly related to the level of epitaxial, chip and packaging, and the industry is currently stuck at an average WPE of 2-3%. The latest UVC devices launched by HYC have a WPE of 6%, a VF of 5-7V, and a typical wavelength of 265-275nm, which ensures the reliability and consistency of the products, and at the same time, the higher WPE brings more light output energy and improves the overall energy utilization efficiency of the industry.

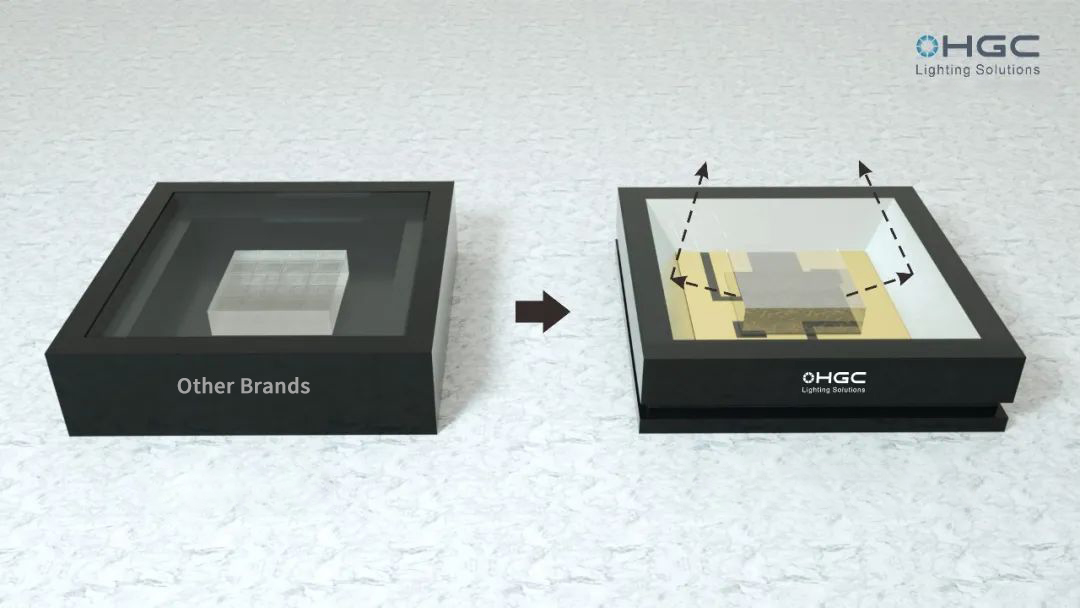

In terms of encapsulation, currently the industry mostly adopts DPC or HTCC bracket, capped with quartz glass lens, while the reflectivity of gold plating layer and Aluminum Nitride surface to UVC is low, about 30% of UVC light is absorbed and lost in the device, HGC has launched the side reflection light-enhancement technology, which is a tilting angle structural design of the monocrystalline silicon material, and at the same time combines with the high reflection of UVC with metal coating technology, which enhances the luminous efficiency by 21% compared with the traditional device; together with the double-sided A-beam A-beam, the light-enhancement efficiency will increase by 21%. 21%; coupled with double-sided AR plating of translucent quartz to further enhance the lens light efficiency, the device WPE is increased to 6%, which can realize the high efficiency optical power output of 35mW@100mA and 170mW@500mA.

Fully Inorganic Package丨Excellent Performance

In terms of hermeticity, HGCC adopts a fully inorganic packaging method, bonding the lens to the support through quartz glass metallization coating technology with temperature resistance >350°C. The entire process uses no organic substances, ensuring high stability and hermeticity of the product.

L70>30,000h 丨Life span is more durable

In terms of thermal management, HGC adopts high thermal conductivity ALN ceramic bracket and eutectic welding process, the effective life of the device is >30,000h, which is at the leading level in the industry, and the power consumption is reduced by 70% compared with the traditional UV light source.

99.99% Sterilization Rate丨Application Upgrade

Up to now, a variety of UVC-LED series products of HGC has passed a number of authoritative tests, such as GWM, ROHS, REACH, and new coronavirus inactivation, and has become the first batch of domestic enterprises with the certification of new coronavirus elimination for UVC sterilization modules. Tested on the environment of Escherichia coli, Staphylococcus aureus, Pseudomonas aeruginosa killing rate of 99.99%; the inactivation efficiency of the new coronavirus (SARS-Cov-2 virus) > 99.99%. Relevant products have been adapted and practically used in a number of medical-grade extermination programs, covering air extermination, surface extermination and water treatment and other application areas, and successfully reached a cooperation with domestic well-known household appliance brands.

The application of UV light source is far more than sterilization. In the future, HGC will accelerate the layout in disinfection and purification, industrial medical treatment, light curing, health education and other applications, focus on the high-end light source track from the chip, packaging, module to the application of the whole industry chain layout, accelerate the R & D process to promote and provide the market with efficient, high-quality UV solutions and customized full chain of services.