HGC LAUNCHED A ONE-STOP VEHICLE LIGHT SOURCE SOLUTION

Mar 25, 2022

The wave of global new energy intelligent vehicles is coming strongly. Small size, intelligence, lamp driver integration and matrix LED lamps have become the mainstream development direction of the automotive lighting market.

HGC has mastered the core technology of international advanced light source research and development, and aimed at the pain points and needs of vehicle light source technology, production, application, and developed a series of vehicle light source products, which can be applied to the front and rear installation markets, providing a one-stop vehicle light source solution from chip, packaging, module to terminal application. The auto light source independently developed by the company has successfully cooperated with well-known auto brands and achieved mass supply.

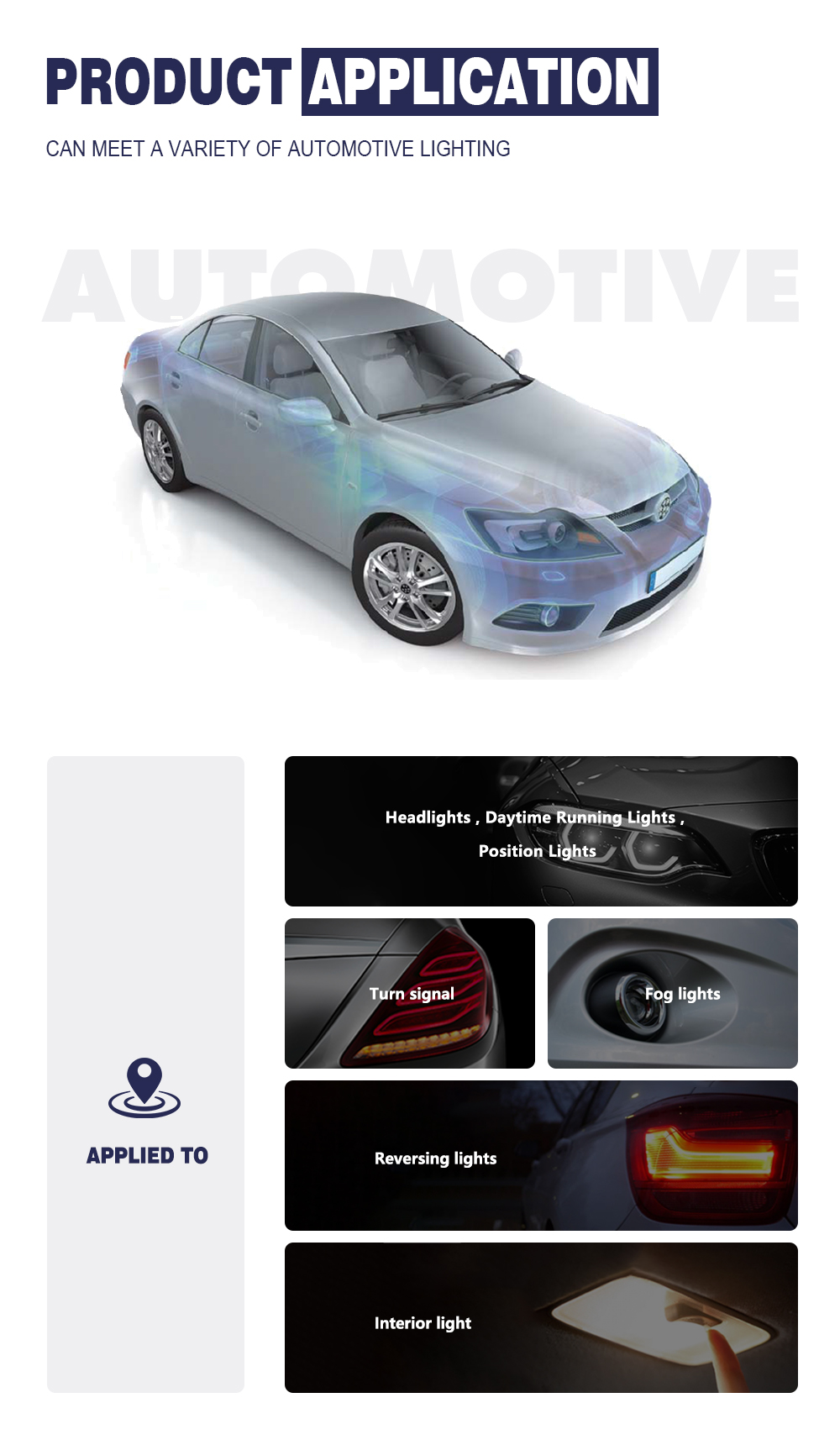

Using the "chip on Tim" technology route, HGC vehicle mounted light source series has the integrated design capabilities of optics, structure, heat dissipation, drive, electronics, etc., and uses self-developed chips and advanced ceramic packaging, SMD epoxy packaging technology to achieve the stringent requirements of the front loading plant for high brightness, high luminous efficiency, high reliability and high heat dissipation capacity of products, which can be applied to front mounted headlights, daytime running lights, position lights, turn signal lights, fog lights Reversing lights and interior lighting have successively passed CE, ROHS, lm-80 product certification and iatf16949 quality system certification.

HGC front mounted daytime running light products are equipped with self-developed vehicle scale chips, with an antistatic grade of 8Kv. With nearly 230w/ (m · K) high thermal conductivity and ultra-high purity ceramic carrier plate, it can achieve rapid heat dissipation and continuous work under high current, and its performance is stable without failure in complex and changeable environments.

Meanwhile,HGC adopts the hot pressing eutectic technology, which can reduce the void rate of the welding surface between the chip and the carrier plate to a very low level, and significantly improve the push and pull strength of the product. The core R & D team of the company continues to carefully study the packaging process to ensure high light efficiency of product output, realize high-strength bonding between chips, carrier plates, white glue and color conversion layers, have stable and consistent structures and good optical effects, and fully meet the application standards of high-end automotive front loading, so as to meet the use needs of customers.

Not limited to exterior lighting (high / low beam lights, direction lights, position lights...), With a comprehensive layout of interior lighting, on-board lidar and on-board backlight display, HGC can provide one-stop vehicle light source solution services for vehicle enterprises, so as to realize the design requirements of cockpit light source with integrated touch display, lightweight, large screen and high-end, and enhance the sense of human vehicle interaction experience.